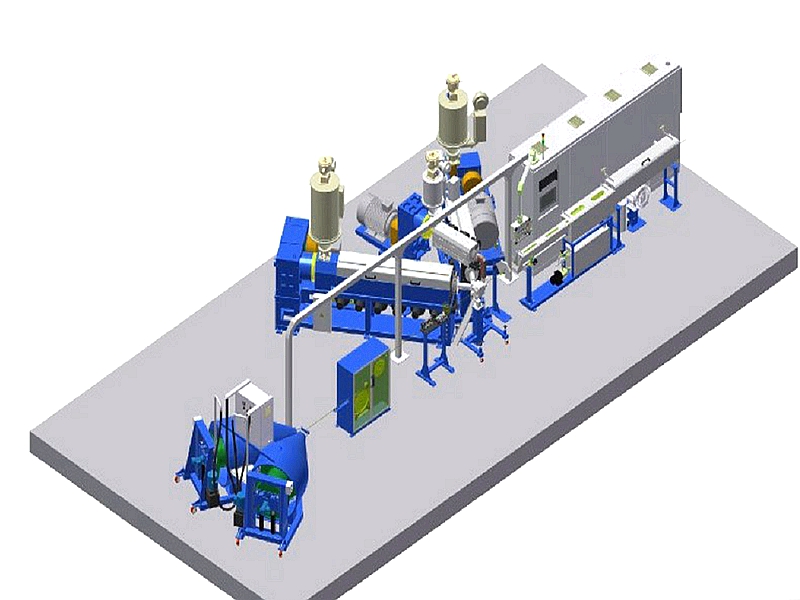

90+45/100+65 High speed insulation line

1.This machine is used for high speed insulation extrusion of electronic wire,building wire,material is suitable to PVC,PE,XLPE and LSHF,HFFR.

2.Suitable for manufacturing single core insulation and multi-core cable sheath such as H05V-U H07V-U H07V-R H05V-K H07V-K , etc .

3.It’s capable of producing different pattern of extrusion,such as single layer,double layer,stripping, skin layer, etc

pay off : 630mm / 800mm

extruder type : 90+45 / 100+65

capstan : 400mm / 500mm

take up : automatic spooler , types: 630mm /800 mm /1250mm

solid stranded wire : 1-2.5mm2 / 1.5mm2-6mm2

materials : PVC / LSHF / HFFR

Line speed : 1200 m/min

PLC+IPC Electric control box

|

No. |

Item |

Figure |

|

1.1.1. |

PLC Controller |

Siemens touch screen 19inch |

|

1.1.2. |

Controlling system |

Heating temperature control Dynamic control Motor control Meters control |

|

1.1.3. |

Consist of |

Total electricity power Inside light Fan Controlling circuit |

|

1.1.4. |

On-time display |

Status of pay-off , take-up , traction separate and synchronizing operation . |

|

1.1.5. |

On-line setting |

Screw RPM Traction speed Line speed Temperature Meter Cold/hot end O.D. |

|

1.1.6. |

Automatic PID control |

Compare the setting diameter and detecting diameter from 2 position , to automatically correcting the manufacturing parameters to maintain the O.D. within tolerance |

|

1.1.7. |

Formula presetting function |

Saving a series of manufacturing parameters such as screw RPM , traction speed , wall thickness , temperature in all zone , to achieve parameters saving . |

|

1.1.8. |

Alarm when defect |

Alarm will set off when defect is detected, such as spark break through, O.D. exceed tolerance . The position , type , quantity , time of the defect will be recorded for freely checking |

|

1.1.9. |

Stop when defect |

Can choose either to stop or not stop when different types of defect is detected |

|

1.1.10. |

Further function |

Could be discussed with our technical staff |

|

1.1.11. |

PLC system |

Siemens S7-1200 SERIES |

|

1.1.12. |

Ethernet port |

Reserved but not necessarily used |

|

1.1.13. |

Communication port |

Siemens S7 |

|

1.1.14. |

Data accumulating system |

On-time collecting and saving the data from the PLC when manufacturing and display on screen , to allow more direct control |

|

1.1.15. |

History function |

Manufacturing parameters history Alarm history Formula saving Stop reason |

|

1.1.16. |

Buttons |

Contains three physical buttons, respectively representing material shortage, equipment repair, abnormal quality. When the operator presses the button, the system will automatically send the signal to the corresponding post, improving the response speed of various functional departments, and the cause of the event will be displayed on the production line screen . |

|

1.1.17. |

Remote checking |

Based on the B/S mode, other devices in the LAN (such as office computers, field pads) can access the system through a browser. The system has a white IP address list. Devices in the white IP address list have the permission to modify device parameters, while devices outside the white IP address list have the permission to view information. |

|

1.1.18. |

MES connection |

Whether SiCAT is connected to MES can be controlled by the switch; The system may periodically send data to the MES system according to the set rules. Can receive work orders and other instruction data issued by MES in real time through standard Restful API interface. |

|

1.1.19. |

Pressure sensor |

Range : 0~100MP Accuracy : ±0.5,1.0%FS Installation screw : 1/2-20 Rod and tube : Rod 70mm , tube 470mm Signal output : 0~10V Exceeding range : 1.5 times of range Max. Environment temp. : 80 degree Detector max. Design temp. : 400 degree |