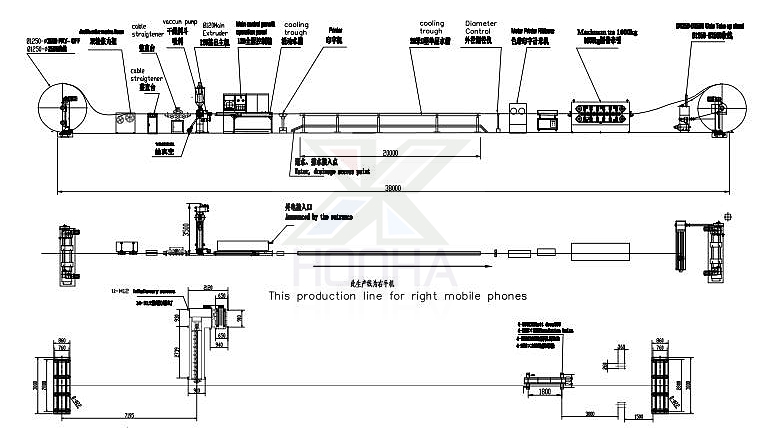

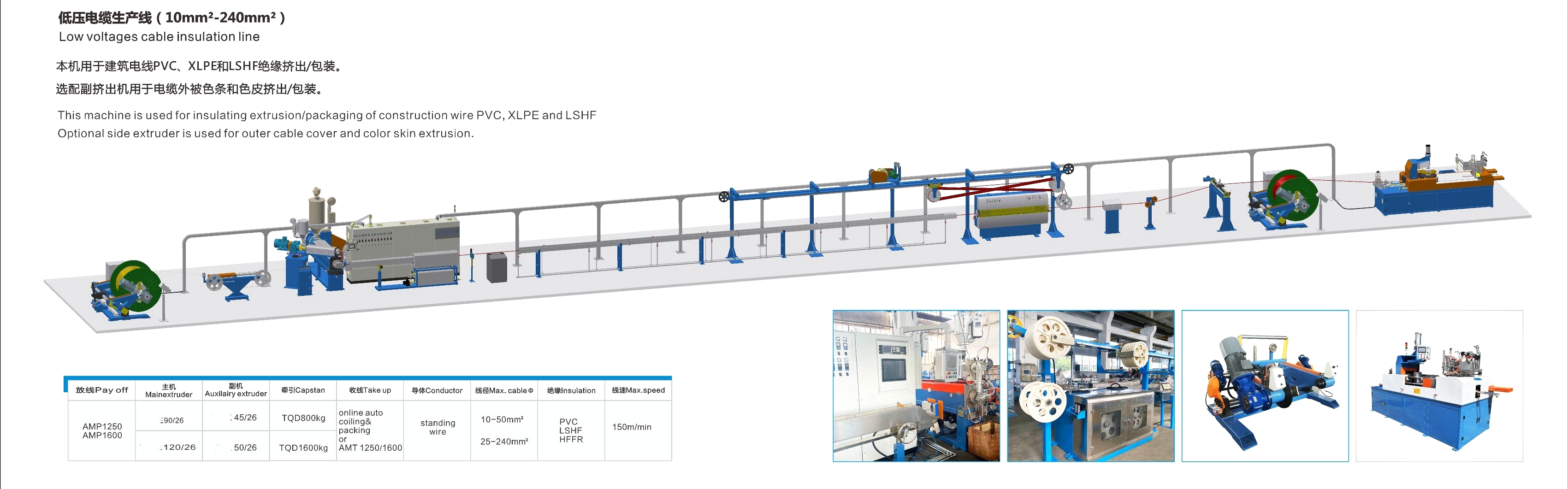

This production line is mainly used for extruding PVC,HFFR,LSHF insulation or jacket for power cable and communication cable etc with section area 50-300 square mm.

♦Precise extrusion process control, the error of extrusion outer diameter can be controlled within ±0.01mm.

♦It can produce high strength, high temperature resistance, aging resistance, chemical resistance, insulation, and flame retardant power cable extrusion screws. The reducer and mold are specially designed to ensure product quality.

♦The whole line can be equipped with Chinese and English man-machine interface, intelligent control, and reliable performance.

♦Life-long maintenance with timely service and low cost.

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

15~60mm |

|

2 |

Finished Wire Diameter |

20~80 mm |

|

3 |

Cross Sectional Area |

100~300 square mm |

|

4 |

Extrusion Speed |

0-150 m/min |

|

5 |

Extrusion Capacity |

400 kg/h |

|

6 |

Installed Capacity |

180 kva |

|

7 |

Voltage |

380V, can be customized |

|

8 |

Weight |

12000 kg |

|

9 |

Measurement (L*W*H) |

55*6*5 m |

|

10 |

Workers recommendation |

3 workers |

Reliable Products:

1.Over 20-year experienced engineer team in field of cable and wire making machines to guarantee professional solution and first-rate quality products.

2.Adopting famous brand parts such as Siemens, Yaskawa, Omron, Emerson to ensure reliable using of our products.

3.We check every detail of the machines and do pre-production test before delivery to eusure products quality and performance.

All-round Service:

1.Our professional engineer team had over 5 years experience working overseas, will provide various technologies to support our customers, including overseas on-site installation guidance, talent training, long-term technological updating services,etc.

2.Our rich-experience sales team will advice your concerns professionally with rigorous working attitude and high communication efficiency.