It is mainly used for PTFE material at wire insulation.

Push extrusion machine is one of the equipment for producing polytetrafluoroethylene wire, this machine will pre-pressing forming machine out of the polytetrafluoroethylene type embryo bar, again pressurized and heated extrusion of higher density polytetrafluoroethylene wire. The machine is set up for pre-pressing forming embryo feeding device, can produce outside diameter 0.8mm-1.5mm wall thickness 0.25-0.5mm wire.

Machine configuration(Production process)

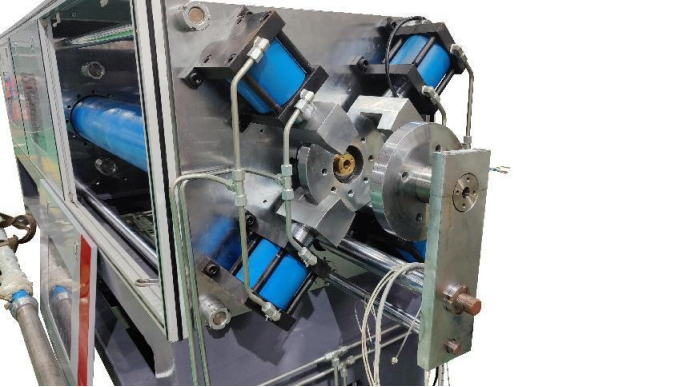

1. Pushing extrusion machine:

1)Application:

Push extrusion machine is one of the equipment for producing polytetrafluoroethylene wire, this machine will pre-pressing forming machine out of the polytetrafluoroethylene type embryo bar, again pressurized and heated extrusion of higher density polytetrafluoroethylene wire. The machine is set up for pre-pressing forming embryo feeding device, can produce outside diameter 0.8mm-1.5mm wall thickness 0.25-0.5mm wire, (outside diameter and wall thickness must match otherwise can not be produced) a production of about 300-800 meters, line speed of about 10-15 meters per minute, the whole machine structure is compact and practical, easy to operate. (Electrical appliances used; Shihlin, Schneider, PLC using Delta or Siemens, touch screen, Willen, servo motor, diameter gauge Oller) push extrusion unit with industrial control system and touch screen control, display all available data, implementation speed, line speed, pushing pressure, are automatically detected, automatic adjustment of speed, temperature at all points, panel layout using the original layout form or according to customer proposed layout, push extruder material cavity φ35, φ35×1300, material rod diameter φ35; push rod part, forward speed regulation automatic speed regulation, return adjustable speed. Material 38CrMoAIA steel tempering treatment, heating using stainless steel heater.

(2) Main parameter:

(1) Servo motor:n=46N*m

Power:4.0KW (With servo controller)

(2) Oil pump:Model PV2R1-6-12

Capacity:6-12cm3/rev

Rated pressure: 1.5Mpa(oil cylinder thrust 60T)

(3) Pushing speed:1~30cm/min(adjustable),

(4) Pushing oil cylinder:oil cylinder diameterφ150

Effective itinerary: 1300mm

(5) Cylinder size:φ35,φ35×1300mm(Includes pusher rod, pusher head)

(6)Push rod head structure: sealed structure

(7)Maximum plunger itinerary: 1300mm

(8)Maximum feeding space:1250mm

The number of heating zones: 2 zones: a total of 4KW (reduce power to ensure smooth heating) heating control using silicon controlled

(9) Billet-making oil cylinder: oil cylinder diameter φ80, effective itinerary 1800mm

(10) Mouth die size: φ35 (can be customized), quantity 2 sets, applicable to oil cylinder diameterφ35mm;

(11) Mouth mold coupling flange: applicable to a set of oil cylinder diameter φ35mm (including heater)

12)Actual feeding material: 1.2Kg per cavity

13)The pushing head is made of POM, with concave end face and ventilated movable head.

14) Pushing and squeezing method is parallel type

(15) clamping mode four-cylinder hydraulic locking, single cylinder 5T

1. Drying and sintering furnace

Main parameters

9.1 temperature control instrument control in 20-450 ℃

9.2 heating power: 26Kw (using 13 tube heaters) heating control using, silicon controlled heating

9.3 Size mm:L x Wx H=1000 x 400 x 400

9.4 Pre-sintered tube φ50 mm stainless steel tube, using the spelling column connected to the heating furnace, vertical sintering, heating furnace stainless steel appearance