1. Machine application

1.1. This machine line is designed for manufacturing cable insulation and sheath with material such as PVC,Nylon.

2. Main specification

2.1.Inlet Wire Diameter:1mm-3.0mm

2.2.Screw Diameter: the screw diameter is 80 mm and 50 mm

2.3. Extrusion Capacity (when the head is turned on): 80 Machine=200 kg/hr(PVC),50 Machine=60 Kg/hr (Nylon)

2.4.Linear Velocity: 0-450 m/min,2.5mm2 is 300 m/min

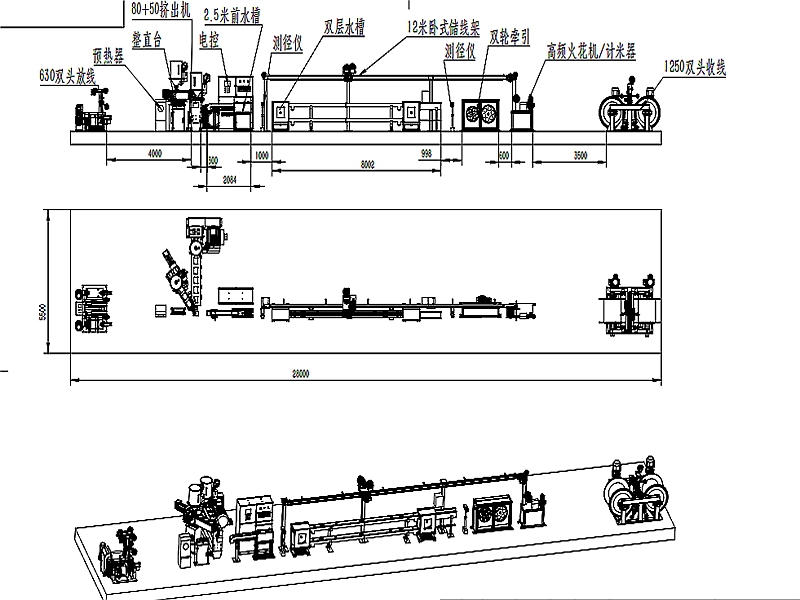

2.5.Length of Production Line: 26 m

2.6.Installed Capacity

Machine Configuration

|

No |

Machine name |

Qty |

Product pics refer |

Noticed |

|

3.1 |

630 double heads motorized pay-off stand |

1 unit |

|

|

|

3.2 |

preheater |

1 unit |

|

|

|

3.3 |

Double wheel straightening workbench |

1set |

|

|

|

3.4 |

80 mm extruder machine |

1set |

|

Single layer |

|

50 extrusion machine |

1 set |

Two layer |

||

|

U14 Extruder head |

1 set |

|

|

|

|

3.5 |

dryer and feeding machine |

2 sets |

|

1.80 extrusion 2.50 extrusion |

|

3.6 |

2.5 meters of movable water tank and 6 meter fixed double layer water tank |

1 unit |

|

|

|

3.7 |

Double wheels capstan Stand |

1set |

|

|

|

3.8 |

12m accumulator stand |

1set |

|

|

|

3.9 |

Measuring-meter platform |

1set |

|

|

|

3.10 |

630-1250 Double-head shaftless motorized take-up stand |

1set |

|

|

|

3.11 |

PLC Electrical control cabinet |

1case |

1.80 extrusion machine 2.50 extrusion machine |

|

|

3.12 |

Spark test machine |

1 set |

|

|

|

3.13 |

Outside diameter testing machine |

1 set |

|

|

|

3.14 |

Display board |

1 set |

|

Can display data (line speed,cable OD)on line |

|

3.15 |

Accessories (self-prepared or separately purchase) |

|||

|

3.15.1 |

Extrusion molding |

14 |

|

|

|

3.15.2 |

Tools |

1 |

l Hex wrench for crosshead clamping * 1 pce l Screw disassembly device * 1 set l Crosshead disassembly device * 1 set l Hex wrench * 1 set (9 pcs) l Flat-head screwdriver * 1 (6 ") l Phillips screwdriver * 1 (6 inches) l Adjustable wrench * 1 (6 inches) l Adjustable wrench * 1 (12 inches) l Vise * 1 l Toolbox * 1 |

|

|

3.15.3 |

Consumable parts |

1 |

l Thermocouple 2 pieces l Fuse 1 piece l Button 2 pieces l Switch 2 pieces l Relay 2 pieces l Heating ring 1 set l Honeycomb board 1 piece l Extrusion head mould 1 set |

|

|

3.15.4 |

Technical documents (optional , if necessary) |

1 |

l Operation manual (including operation instruction, dies series chart, install instrument, error solution, maintenance, easy to wear parts drawing, electrical wire connection diagram) l main electrical part operation manual l Foundation drawing (including water ,air, power connection indication diagram, based on supplier’s requirement , this drawing shall be confirmed within 30 days when contract becomes effective) l Bobbin drawing shall be confirmed with 30 days from the effective day |

|

|

3.15.5 |

Custom document |

1 |

l Packing list l Quality certificate l Other as required |

|

|

3.16. Machine color

|

||||

|

No. |

Main part |

Stand color |

Customize color |

|

|

3.16.1 |

Mechanical part |

RAL5012 , RAL9003 |

Specified if needed |

|

|

3.16.2 |

Electrical part |

RAL7035 |

Specified if needed |

|

|

3.16.3 |

Protection door ,cover and rotating part |

RAL2011 |

Specified if needed |

|

|

3.16.4 |

Stainless steel part |

Original color |

|

|

|

Others shall be executed according to the supplier's factory standard. When selecting the international color standard, the supplier shall provide it to the demander for confirmation according to the color standard plate, and spray paint shall be performed according to the color plate confirmed by both parties. Demander understands and agrees to accept that variation in color difference is permitted. The Demander shall, within one week after receiving the color plate provided by the Supplier, give the Supplier a seal to confirm the color plate and send it back to the Supplier. If the delivery is overdue, the delivery time will be postponed. |

||||

|

3.17 |

Operation direction |

Left side for inlet of wire and right side for taking up while operator faces to the drawing machine. |

Or reverse as customized |

|