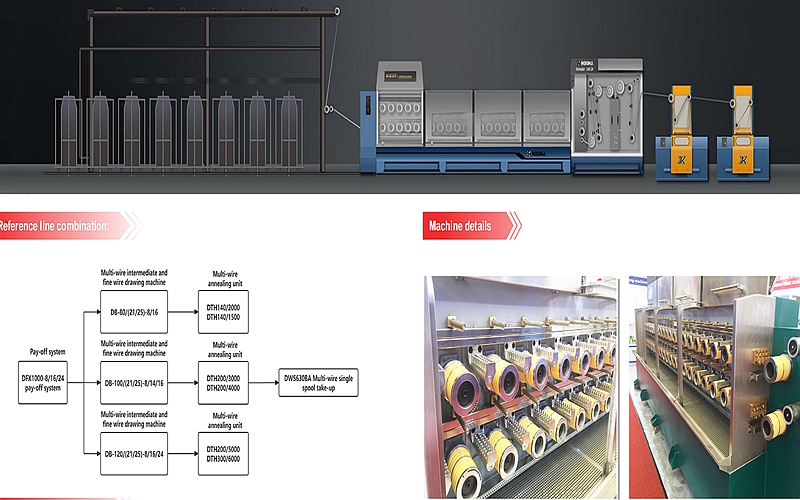

1.Machine components

|

Machine specification |

Qty |

|

8 heads pay off frame |

1 set

|

|

8 heads small and medium-sized wire drawing machine |

1 unit |

|

DTH200-4000 annealing machine |

1 unit |

|

YG250 Tension Rocker |

1 unit |

|

DWS630 Disc Spooler |

1/2 unit |

|

Electrical control systems |

1 set |

2.Overall equipment parameters

|

parameter term |

Parameters |

Notice |

|

Inlet raw materials |

Low-oxygen or oxygen-free round copper wire |

|

|

Specification of incoming wires |

Max8*Ф1.8 mm and 8*Φ2.60mm |

Tensile strength 250N/mm² |

|

Total installed capacity: |

492KVA |

Electricity for peripheral auxiliary equipment is not included. |

|

Total external dimensions: |

L x W x H : 24mx6.5mx4m |

Subject to standard foundation layout drawings provided by the supplier. |

|

Total weight: |

About 15000Kg |

Subject to physical weight. |

|

Scope of production: |

Soft wire: 1.8mm inlet: 8*0.28mm-0.64mm; 2.6mm inlet: 8*0.40mm-1.05 |

|

3.Technical parameters and configuration of modular equipment

|

8 multi-head payoff frame |

|

|

Inlet guide wheel diameter |

Ф126mm |

|

Diameter of over-wire guide wheel |

Ф126mm |

|

Unwind speed |

Max 100m/min |

|

Threading method |

Climbing ladders and platforms |

|

Column change method |

manually operated |

|

Maximum diameter of fence |

Ф1100mm |

|

Number of rails that can be placed |

8 |

|

Straightening wheel diameter |

Ф38mm |

|

Equipment weight |

1375 kg |

|

Reference equipment size L*W*H |

5920mm*2170mm*4000mm |

|

Main components selection |

|

|

Inlet guide pulleys |

Nylon |

|

Cable guide pulleys |

Nylon |

|

bear |

Domestic Bearings |

|

8 Multi-head Drawing Machine |

|

|

Boundaries of the line |

7*Ф0.40mm~Ф1.05mm; 8*Ф0.28mm~Ф0.56 mm |

|

extent of approach |

Max 7*Ф2.6mm/8*Ф1.8 mm (tensile strength 250N/mm²) |

|

Maximum mechanical speed |

1800 m/min |

|

Applicable raw materials |

Low Oxygen / Oxygen Free Round Copper Rods |

|

Drawing main motor power |

AC 200kW |

|

Fixed-speed motor power |

AC 55kW |

|

control method |

AC control |

|

Drawing Drum Wheel Diameter/Number |

120 mm (15 total) |

|

Diameter of fixed speed wheel |

120 mm |

|

mechanical transmission ratio |

1-15 mold 1.25/sizing 1.184 |

|

Maximum number of passes |

16 |

|

Die O.D. * Thickness |

Ф25 mm*12mm |

|

body structure |

A3 steel plate welding |

|

Drawing wheel cooling lubrication method |

Power Spray |

|

Operating Direction |

Rightward (facing the drawing mainframe, feeding the wire from the left and closing it on the right) |

|

Equipment weight |

Approx. 5900 kg |

|

Equipment reference size L*W*H |

5.3mx1.3mx1.3m |

|

installed capacity |

260kVA |

|

Main components selection |

|

|

Auxiliary drive |

Dongguan motor |

|

Fixed speed motor |

Dongguan motor |

|

Brushed rims |

Zirconia (Made in China) |

|

Fixed-speed rims |

Zirconia (Made in China) |

|

Spindle bearings |

Japan NSK |

|

Main Low Voltage Appliances |

Schneider |

|

converter |

Japan Yaskawa |

|

Programmable logic controller (PLC) |

Siemens |

|

touchscreens |

Siemens |

|

Conditions of use of equipment (it is the responsibility of the equipment user to provide the following conditions and to meet the relevant standard values) |

|

|

Ambient temperature |

0℃~40℃ |

|

Ambient humidity |

≤85% (at a temperature of 20°C ± 5°C) |

|

Applicable altitude |

≤1000m |

|

power supply |

Three-phase voltage: 3×380V (-5%~+10%) |

|

Single-phase voltage: 220V (-5% to +10%) |

|

|

Power supply frequency: 50Hz (±2%) |

|

|

Parameters of drawing solution |

Concentration: 6% to 10% |

|

PH value: 8.5~9 |

|

|

Working pressure: 0.1~0.2 Mpa |

|

|

Inlet temperature: ≤35℃ |

|

|

Flow rate: 36 m3 /h |

|

|

Conductivity of soft water for hooking and drawing solution: ≤10μS/cm |

|

|

Conductivity: ≤3000μS/cm |

|

|

Cooling water parameters |

Working pressure: 0.2~0.4 Mpa |

|

Inlet temperature: ≤30°C |

|

|

PH: 7 |

|

|

Flow rate: 30 m³/h (5 m³/h cooling for oil + 25 m³/h cooling for drawing fluid) |

|

|

Hardness: ≤8dH |

|

|

Basic requirements: The water source must not contain suspended solids, minerals, metallic impurities, insoluble and corrosive substances. |

|

|

Gear oil parameters |

Recommended brand model: Great Wall Industrial Gear Oil AP100 (domestic users) BP-Energol GR-XP100 (foreign users) |

|

Consumption: about 430L |

|

|

User-provided molds and other equipment and facilities (recommended usage) |

20m2 plate heat exchanger |

|

7.5HP pipeline pump (less than 30m from the drawing oil tank to the supply port) |

|

|

Wire drawing die (based on the supplier's die sheet) |

|

|

mill |

|

|

cold welder |

|

|

Copper powder filter |

|

|

50T cooling tower |

|

|

5m³ Drawing liquid pool |

|

|

10m³ clear water tank |

|

|

DTH200-4000-8 multi-head annealing machine |

||

|

Applicable raw materials |

Oxygen-free round copper wire |

|

|

Scope of production |

7*Ф0.70mm~Ф1.05mm; 8*Ф0.28mm~Ф0.64 mm |

|

|

Maximum mechanical speed |

1800 m/min |

|

|

Contact wheel diameter |

200 mm |

|

|

Blow-drying mold O.D. Thickness |

Ф4mm x 4mm |

|

|

Annealing current |

Max 4000A DC |

|

|

Annealing voltage |

Max 51V DC |

|

|

Annealing method |

DC Contact |

|

|

Drive control mode |

Fixed speed flat belt drive |

|

|

Conductive wheel cooling method |

water cooling |

|

|

protective gas |

helium |

|

|

body structure |

A3 steel plate welding |

|

|

Collector ring cooling system |

0.3m3 Stainless steel tank |

|

|

3m2 plate heat exchanger |

||

|

1HP immersion multistage centrifugal pumps |

||

|

Annealing fluid cooling system |

0.5m3 water tank |

|

|

12m2 plate heat exchanger |

||

|

3HP immersed multistage centrifugal pumps |

||

|

Operating Direction |

Rightward (facing the annealing mainframe, with the wire entering from the left and closing on the right) |

|

|

Equipment weight |

4800kg |

|

|

Equipment reference size L*W*H |

2640mm*1525mm*2285mm |

|

|

installed capacity |

215kVA |

|

|

Main components selection |

||

|

Annealing Controller |

Sichuan Yingjie |

|

|

Annealing transformers |

Aiyueide |

|

|

Main Low Voltage Appliances |

Schneider |

|

|

Spindle bearing |

SKF Sweden |

|

|

drive flat belt |

Swiss Habasi |

|

|

Contact ring material |

Nickel Alloy Materials |

|

|

Cable guide pulleys |

Ceramic spraying treatment on the groove surface |

|

|

touchscreens |

Siemens or equivalent |

|

|

Random spare parts |

||

|

Connecting conductive copper rows |

1 group |

|

|

Annealed contact rings |

1 piece |

|

|

Annealed carbon brushes |

8 pieces |

|

|

Note: Connecting conductive copper row lengths are provided in accordance with the equipment's standard foundation plan. |

||

|

Conditions of use of equipment (it is the responsibility of the equipment user to provide the following conditions and to meet the relevant standard values) |

||

|

Ambient temperature |

0℃~40℃ |

|

|

Ambient humidity |

≤85% (at a temperature of 20°C ± 5°C) |

|

|

Applicable altitude |

≤1000m |

|

|

power supply |

Three-phase voltage: 3×380V (-5%~+10%) |

|

|

Single-phase voltage: 220V (-5% to +10%) |

||

|

Power supply frequency: 50Hz (±2%) |

||

|

Nitrogen Requirements |

Working pressure: 0.3Mpa |

|

|

Fluctuation value: ±0.02Mpa |

||

|

Dew point: -40°C |

||

|

Flow rate: 1 m3 /h |

||

|

Purity: 99.99% |

||

|

Compressed air requirements |

Working pressure: 0.6~0.7Mpa |

|

|

Fluctuation value: ±0.02Mpa |

||

|

Dew point: -25°C |

||

|

Flow rate: 80 m3 /h |

||

|

Annealing fluid parameters |

Concentration: 0.6% to 1% |

|

|

PH value: 7.5~8 |

||

|

Working pressure: 0.2~0.4 Mpa |

||

|

Inlet temperature: ≤35℃ |

||

|

Flow rate: 24 m3 /h |

||

|

Conductivity: ≤300μS/cm |

||

|

Soft water conductivity of hook annealing solution: ≤10μS/cm |

||

|

Collector ring coolant |

Complete deionized water + glycol solution Concentration: 2% |

|

|

(Fully deionized water) PH value: 6.7~7.5 Conductivity: ≤140μS/cm Total hardness: about 4 degrees Carbonate hardness: about 2 degrees |

||

|

Working pressure: 0.3 Mpa |

||

|

Inlet temperature: ≤30°C |

||

|

Flow rate: 5 m3 /h |

||

|

Cooling water parameters |

Working pressure: 0.2~0.4 Mpa |

|

|

Inlet temperature: ≤30°C |

||

|

PH: 7 |

||

|

Flow rate: 27 m³/h (3 m³/h cooling for collector exchange + 24 m³/h cooling for annealing liquid) |

||

|

Hardness: ≤8dH |

||

|

Basic requirements: The water source must not contain suspended solids, minerals, metallic impurities, insoluble and corrosive substances. |

||

|

Molds and other equipment and facilities |

Blow-drying molds |

|

|

Copper powder filter |

||

|

15m³ clear water tank |

||

|

Outlet wire diameter |

production speed |

Annealed elongation |

|

8*0.28 mm |

1200 m/min (Grade A copper rod) |

18-25% |

|

8*0.30 mm |

1200 m/min (Grade A copper rod) |

25-33% |

|

8*0.40 mm |

1200 m/min (Grade A copper rod) |

25-33% |

|

8*0.50 mm |

1200 m/min (Grade A copper rod) |

25-33% |

|

8*0.60 mm |

1100 m/min (Grade A copper rod) |

25-33% |

|

7*0.80 mm |

500 m/min (Grade A copper rod) |

25-33% |

|

7*1.05 mm |

250 m/min (Grade A copper rod) |

25-33% |

|

YG250 Tension Rocker |

|

|

Suitable for spooler models |

WS series single-disk take-up machine, WF series plum blossom drop wire machine |

|

Diameter of over-wire guide wheel |

250mm |

|

Maximum number of laps |

1 |

|

counterweight |

aerodynamic |

|

Equipment weight |

Approx. 250kg |

|

Reference equipment size L*W*H |

900mm*410mm*1900mm |

|

Main components selection |

|

|

Cable guide pulleys |

Ceramic spraying treatment on the groove surface |

|

bear |

Japan NSK or equivalent |

|

Main pneumatic components |

Taiwan or equivalent brands |

|

Random spare parts |

|

|

Tension potentio meters |

1 pc |

|

proximity switch |

1 pc |

|

Conditions of use of the equipment (it is the responsibility of the equipment user to provide the following conditions and to meet the relevant standard values) |

|

|

Compressed air requirements |

Working pressure: 0.6~0.7Mpa |

|

Fluctuation value: ±0.02Mpa |

|

|

Dew point: -25°C |

|

|

Flow rate: 3m3 /h |

|

|

Note: Compressed air must be dry, clean and free of oil. |

|

|

DWS630 Disc Take-up Machine |

|

|

Take-up wire diameter |

8*0.28mm-0.64mm |

|

Maximum mechanical speed |

2000 m/min |

|

Take-up motor power |

AC 15kW |

|

control method |

AC control |

|

Servo wiring motor power |

1000 W |

|

Platoon motor power |

15 W |

|

Ribbon capacity (max) |

500 kg (copper) |

|

Reel Specifications |

PND500 or PND630 (designed and manufactured in accordance with bobbin drawings determined by the parties) |

|

braking method |

pneumatic brake |

|

Tray loading operation method |

Pneumatic (double top shaft) |

|

Operating Direction |

Suitable for wire drawing machines |

|

Installed capacity of take-up machines |

17kVA |

|

Equipment weight |

2530 kg |

|

Equipment reference size L*W*H |

1350mm*2050mm*2230mm |

|

Main components selection |

|

|

regulating wheel |

Spray ceramic treatment on the groove surface |

|

auxiliary drive |

Dongguan motors or equivalent quality substitutes. |

|

Spindle bearings |

Japan NSK or equivalent quality substitutes. |

|

Main Low Voltage Appliances |

Schneider or equivalent quality alternatives. |

|

Main motor drive inverter |

Shenzhen Huichuan or equivalent quality substitutes. |

|

Main pneumatic components |

Taiwan or equivalent quality substitutes. |

|

Random spare parts |

|

|

Wire Guide Wheel |

1 |

|

Conditions of use of equipment (it is the responsibility of the equipment user to provide the following conditions and to meet the relevant standard values) |

|

|

Ambient temperature |

0℃~40℃ |

|

Ambient humidity |

≤85% (at a temperature of 20°C ± 5°C)

|

|

Applicable altitude |

≤1000m |

|

Applicable power supply |

Three-phase voltage: 3×380 V (-5%~+10%) |

|

Single-phase voltage: 220 V (±10%) |

|

|

Power supply frequency: 50 Hz (±2%) |

|

|

Compressed air requirements |

Working pressure: 0.6~0.7Mpa |

|

Fluctuation value: ±0.02Mpa |

|

|

Dew point: -25°C |

|

|

Flow rate: 3m3 /h |

|

|

Note: Compressed air must be dry, clean and free of oil. |

|