This page aim to help those who want to set up a optic fiber cable factory to have a better understanding of the structure and types of optic fiber cable ,

Also the relevant machinery to produce them . This page will consist of :

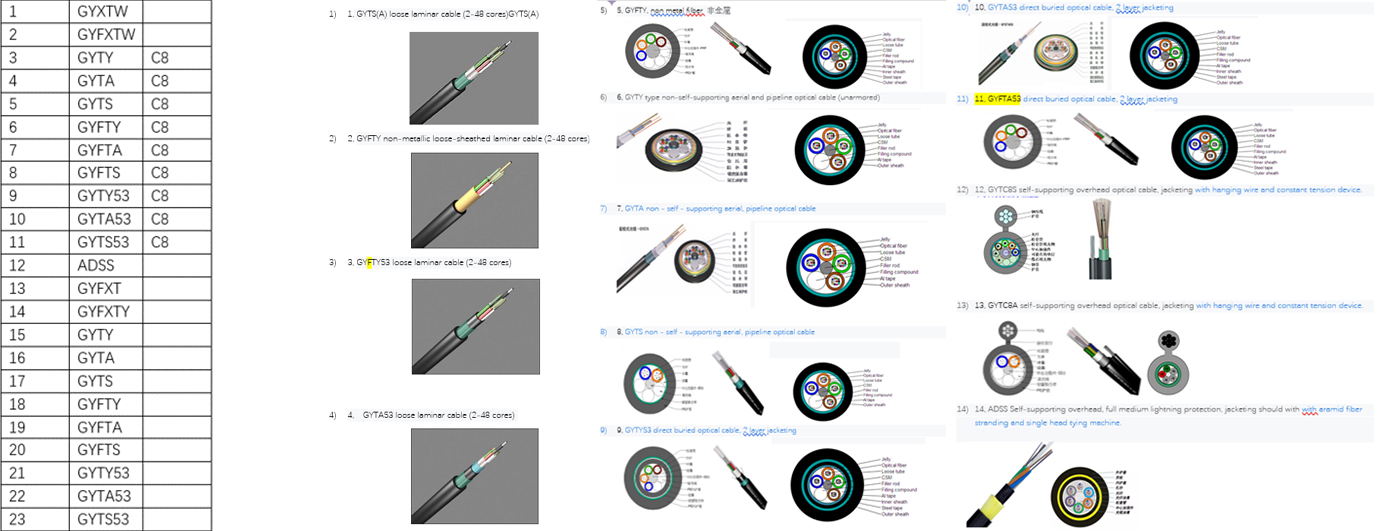

Ⅰ.Optic fiber nomenclature

Ⅱ.General optic fiber cable types

Ⅲ.Core structure of Optic fiber cable

Ⅳ.Related machinery

Ⅴ.Plant accessories

HOOHA has the capacity to provide full factory solution to those who has a clear picture in cable industry including optic fiber cable , from manufacturing machinery to factory accessories .

So pls contact us at the end of the page with detailed inquiry .

Also we can offer guidance to those who want to start business in cable industry but without accurate idea .

| Classification | Reinforcement member | Structural characteristics | Sheath(inner) | Sheath(outer) | |||||

| Code | Meaning | Code | Meaning | Code | Meaning | Code | Meaning | Code | Meaning |

| GY |

Outdoor optical cable for communication |

/ | Metal Reinforcement | / | Concentric stranding | Y | PVC | 1 | Fiber sheath |

| GM | Mobile optical cable for communication | F | Non-metal Reinforcement | S | Loose tube | V | PE | 2 | PVC sheath |

| GJ | Indoor optical cable for communication | G | Heavy metal reinforcement | J | Tight buffer | F | Fluoroplastic | 3 | PE Sheath |

| GS | Optical cable in communication equipment | H | Heavy non-metal reinforcement | D | optic fiber cable ribbon | U | PU | 4 | PE+Nylon sheath |

| GH | Undersea cable for communication | G | Skeleton groove | E | ELASTOMER | 5 | PE Tube | ||

| GT | Special optical cable for communication | X | Central tube | A | Aluminum tape-PE attached sheath | ||||

| GR | Flexible optical cable for communication | T | Filler | S | Steel tape-PE attached sheath | ||||

| B | Flat | W | Steel tape-steel wire-PE attached sheath | ||||||

| Z | Flame-resistant | L | Aluminum | ||||||

| C | Self-support | G | Steel | ||||||

| E | Oval | Q | Lead | ||||||

| 0 | Non-Armoured | ||||||||

| 2 | Double steel tape | ||||||||

| 3 | Thin Steel wire | ||||||||

| 4 | Thick steel wire | ||||||||

| 5 | Corrugated steel tape | ||||||||

| 6 | Double steel tape | ||||||||

| Name | Model | Structure | Install method |

| Central tube | GY X T Y | Outdoor telecom optic fiber cable 、metal Reinforcement、Central tube 、Filler 、with reinforcement PE sheath | Aerial 、agricultural |

| GY X T S | Outdoor telecom optic fiber cable 、metal Reinforcement、Central tube 、Filler 、Steel tape-PE attached sheath | Aerial、agricultural | |

| GY X T W |

Outdoor telecom optic fiber cable 、metal Reinforcement、Central tube 、Filler 、with parallel steel wire 、Steel tape-PE attached sheath |

Aerial、pipe、agricultural | |

| Concentric stranding | GY T A | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、Aluminum tape-PE attached sheath | Aerial、pipe |

| GY T S | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、Steel tape-PE attached sheath | Aerial、pipe、Direct bury | |

| GY T A 53 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、Aluminum tape-PE attached sheath、Corrugated steel tape armoring PE outer sheath | Direct bury | |

| GY T Y 5 3 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、Corrugated steel tape armoring PE outer sheath | Direct bury | |

| GY T A 3 3 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、Aluminum tape-PE attached sheath、single thin steel wire armoring 、PE outer sheath | Slope direct bury | |

| GY T Y 53+33 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、Corrugated steel tape + single thin steel wire armoring、PE outer sheath | Direct bury、submersible | |

| GY T Y 53+333 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、Corrugated steel tape + single thin steel wire armoring、PE inner sheath + double thin steel wire armoring、PE outer sheath | Direct bury、submersible | |

| optic fiber cable ribbon | GY D X T W | Outdoor telecom optic fiber cable 、metal Reinforcement、fiber ribbonCentral tube 、Filler 、with parallel steel wire 、Steel tape-PE attached sheath | Aerial、pipe、access |

| GY D T Y | Outdoor telecom optic fiber cable 、metal Reinforcement、fiber ribbon、Loose tube concentric stranding 、Filler 、PE sheath | Aerial、pipe、access | |

| GY D T Y 53 | Outdoor telecom optic fiber cable 、metal Reinforcement、fiber ribbonLoose tube concentric stranding 、Filler 、PE inner sheath、Corrugated steel tape armoring PE outer sheath | Direct bury、access | |

| GY D G T Z Y | Outdoor telecom optic fiber cable 、metal Reinforcement、fiber ribbon、Skeleton groove、Filler 、LSZH sheath | Aerial、pipe、access | |

| Non-metallic optic fiber cable | GY F T Y | Outdoor telecom optic fiber cable 、Non-metal Reinforcement、fiber ribbon、Filler 、PE sheath | Aerial、HV area |

| GY F T Y 0 5 | Outdoor telecom optic fiber cable 、Non-metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、non-armored、PE sheath | Aerial、channel、HV area | |

| GY F T Y 0 3 | Outdoor telecom optic fiber cable 、Non-metal Reinforcement、Loose tube concentric stranding 、Filler 、non-armored、PE sheath | Aerial、channel、HV area | |

| GY F T C Y | Outdoor telecom optic fiber cable 、Non-metal Reinforcement、Loose tube concentric stranding 、Filler 、self-support PE sheath | Self-supported | |

| Power optic fiber cable | GY T C 8 Y | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、self-support 、8 type 、 PE sheath | Self-supported |

| Flame-resistant optic fiber cable | GY T Z X | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、Steel-LSZH attached sheath | Aerial、pipe、non-smoke scenario |

| Anti-ant optic fiber cable | GY T A 0 4 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、non-armored、PE+Nylon sheath | pipe、anti-ant scenario |

| GY T Y 5 4 | Outdoor telecom optic fiber cable 、metal Reinforcement、Loose tube concentric stranding 、Filler 、PE inner sheath、Corrugated steel tape armoring 、PE+Nylon sheath | Direct bury、anti-ant scenario | |

| Indoor optic fiber cable | GJ F J V | Indoor optical cable for communication、Non-metal Reinforcement、Tight buffer、PE sheath | Indoor terminal or patch cord |

| GJ F J Z Y | Indoor optical cable for communication、Non-metal Reinforcement、Tight buffer、LSZH sheath | Indoor terminal or patch cord | |

| GJ F D B Z Y | Indoor optical cable for communication、Non-metal Reinforcement、fiber ribbon、Flat、LSZH sheath | Indoor terminal or patch cord |

Specialized fiber cable independent from above nomenclature:

Optic fiber cable :SIMPLE/DUPLEX Optic fiber cable , FTTH(Fiber To The Home)

Special optic fiber cable :ADSS (All-Dielectric Self-Supporting optic fiber cable)

A.Fiber core (↑)

Equal to copper/aluminum conductor in normal cable , the carrier that realizes the signal transmission

Fiber core is generated by optical fiber preforming machine and wire drawing tower, these two kinds of equipment need to be used together, and these two sets are of equipment high output, fast speed, high investment cost, technical content demand, so generally only in the mass production will be equipped. Roughly equivalent to the CCR line in the copper/aluminum cable industry .

In actual production, sometimes it is necessary to use special optical fiber coloring machine to color colorless fiber core.

Indoor optical cable, simple optical fiber line, the use of fiber core generally does not need to be colored, the purpose of coloring is to distinguish each fiber in the production and use of optical fiber, but most of indoor optical fiber is adopt tight buffer structure with only one core, so in the production of these two kinds of optical fiber, even if the need to color, the maker will still a direct purchase of colored fiber core as raw material, Regucing the cost of this machine.

Related machinery

1) Optic fiber preforming&drawing machine

2)Fiber coloring machine

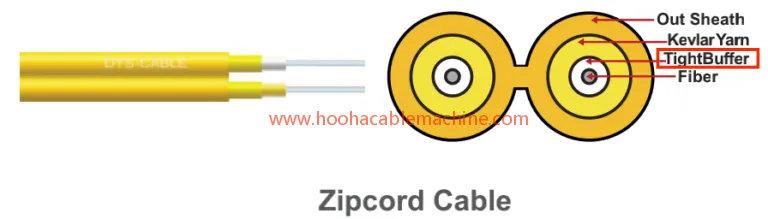

B.Tight buffer (TB)

Note that tight buffer is the name of the structure , not the surface material ,

The extrusion material can be : PVC、LSZH、Hytrel、Nylon、TPU

The structre is 1 fiber core extruded and claded with 1 layer of tight buffer . Generally used in Indoor optic fiber cable , and the color of the tight buffer is different , so the coloring machine is unnecessary .

Related machinery

30 tight buffer extrusion machine

Relevant optic fiber cable :

C.Loose tube / secondary coating

Loose tube structure is widely used in outdoor optic fiber cable .

Structure is : 1-12 fiber core/4-24 fiber ribbon + Jelly + loose tube layer

The extrusion layer material could be PBT ,modified PP and PE .

Related machine

50/70 Loose tube extrusion line

Note : the pay-off of this machine could be changed based on the structure : cage type motorized pay-off , with additional S/Z stranding device .

Cage type motorized pay-off

Movable S/Z stranding device

Relevant optic fiber cable

D. Jelly

Its main function is lubrication , water proof and buffer protection .

Jelly is usually non-hygroscopic. It's existing in the sheath of the cable. The type used during telecom installation. They make cables durable

and are ideal for wear resistant use.

Related machine:

Specialized applying device with bubble removal vacuum to ensure there is no affection and bubble , make the barrier more stable .

Usually will function as a attached device in loose tube extruder , S/Z laying up strander , Outdoor optic fiber cable cable sheath extruder :

Relevant optic fiber cable :

E. Aramid

Aramid is fiber material to provide tensile strength in cable . It’s tough and Helps tie loose pipes during and after installation .

Used both in outdoor and indoor optic fiber cable .

There are 3 methods to add the aramid fiber : lateral drag , concentric stranding , S/Z twisting fixed

Mainly function on sheath extruder with synchronized unit , not a exclusive machine . Can comprehend as the 4 head lateral taping unit and armoring unit on the laying-up machine .

Related machine:

1.Lateral dragging

2. Concentric stranding

3. S/Z stranding device

Relevant optic fiber cable :

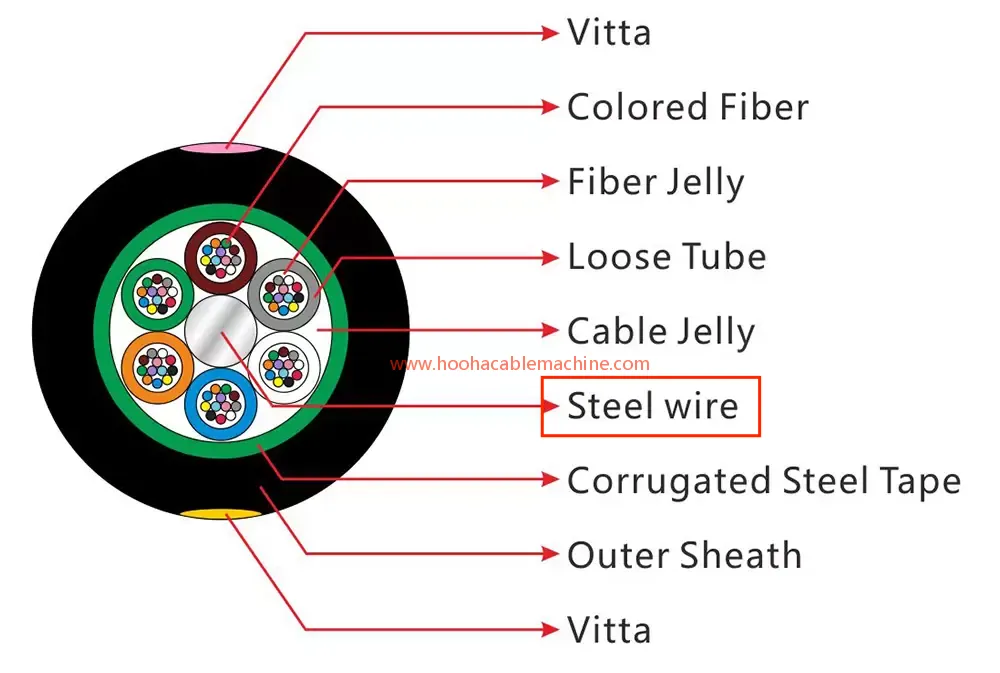

F. Steel wire , Non-metallic reinforcement member - FRP

Like ordinary cables, the purpose of steel wire is to provide structural strength.

There is 2 method to add this structure , 1 is to lateral drag into the sheath , another is to function as the core in the concentric stranding structure optic fiber cable

Widely used in FTTH and outdoor optic fiber cable .

Compared with the same structure reinforced structure of steel wire, it has a better high strength/weight ratio, so it is more suitable for twisting, and because of the excellent anticorrosion, so it is more suitable for frequent rain areas .

Related machine:

1. Steel wire/FRP pay-off in extruder

Note: the actual placement is placing on the side .

1. Steel wire/FRP pay-off in 800 S/Z strander

Relevant optic fiber cable

Steel wire

FTTH

FRP

G. Steel tape armoring

Steel tape armor in optic fiber cable generally adopts the form of laser welding after towing (longitudinal wrapping), and then corrugating .

Of course, according to the demand, can also be done in the form of non-rolling.

Related machinery :

This process is not normally done in a separate machine, but is integrated into the outer cable sheath extrusion line .

Device order in the red highlighted area : (right to left) steel/Aluminum tape pay-off , tape tip welder , tape storage device , metal corrugating device , tape lateral foaming device .

Relevant optic fiber cable :

H.Taping - waterproof taping / Aluminum PE

Because optical fibers transmit optical signals at work, the bands in the fiber don't need to act as a signal insulator, as traditional signal wires do.

The main function of the wrapping is to fix the stranded (S/Z stranded technology leads to the stranded body is not tight), protection and waterproof.

The way the tape is wrapped is different at different locations

Related machinery :

When attaching in the sheath extruder line

Concentric taping unit in S/Z stranding line

Relevant optic fiber cable :

I. Sheath

Personally I think the sheath line is the most complicated machine line in optic fiber cable manufacturing Because many structures and processes of optical fiber will be added to the final sheathing extruder in the form of small structures.

To be simple , it means the structures mentioned above will be added into the sheath line before the main extruder - aramid yarn , steel wire , FRP , steel tape armoring , Jelly ,water

block taping . Also the following water trough , guide wheel , storage rack , traction wheel , take-up unit will be slightly different than normal extruder .

Material for indoor optic fiber cable sheath :PVC , LSZH , HDPE

Material for outdoor optic fiber cable sheath :HDPE , LSZH

Material for FTTH : HDPE

Sample machine:

1. Simplex and Duplex Premises Cable extrusion Line,50 model , additional device : aramid lateral drag .

2. Multi Purpose Premises Cable extrusion Line,70 model ,additional device :cage type stranding pay-off , steel wire lateral dragging .

3. Outdoor optic fiber cable sheath extrusion line , 90 model , additional device : aramid cage stranding pay-off , jelly , tape stranding , water proof taping .

Relevant optic fiber cable :

A. Bobbin and reels (Can be supported by HOOHA)

| Pay-off | 25Km | 50Km | 50Km |

| Flange Diameter | 236mm | 236mm | 265mm |

| Barrel Diameter | 160mm | 160mm | 160mm |

| Width | 108mm | 230mm | 170mm |

| Bore Diameter | 25.4mm | 25.4mm | 25.4mm |

| Reel Weight | 5kg | 10kg | 10kg |

| Take-up | PN800 | PN1000 |

| Flange Diameter | 800mm | 1000mm |

| Barrel Diameter | 400mm | 507mm |

| Width | 630mm | 750mm |

| Bore Diameter | 80mm | 80mm |

B.Extrusion Tips and Dies (Can be supported by HOOHA)

6.Payment method

T/T

7.Delivery Time in general

60 days

8.Product Packaging

|

|

|

The plastic+wood packing |

The wood packing |

The fixed by steel or tap |

| The usually packing way is plastic packing | The wood package will according to the customer's inquiry then design to wood packing | The machine will fixed by the steel rope and Tap in the container |

|

|

|

10.Exhibitions of HOOHA

|

|

11.Customer Cases of HOOHA

|

|

|

|

|

|

12.Professional Engineers and Experienced Sales Team of HOOHA

|

|

|

|

|

Professional Engineers and Experienced Sales Team

|

|||||

| Name | Education | Position | Mainly responsible for project | Specializing in project | Working history ( year ) |

| Zanyang Xie | college | General Engineer | The total project design and planning | power cable machine | 15 |

| Xiaohua Hu | college | Vis general engineer | The total project design and planning | net cable,data cable machine | 10 |

| Changhong Cheng | college | Engineer | Drawings and after-sales service | Optical fiber cable machine | 25 |

| Xiuwu Chen | college | General Engineer | The total project design and planning | copper drawing machine | 15 |

| Lixin Yuan | college | Engineer | The project design and planning | coppwer wire making technical | 16 |

| Zhenghai Qiu | college | cable engineer | After service | cable making and cable factory management servie | 15 |

| Jinxin Liu | college | Marketing engineer | After service | electrical engineer | 7 |

| Xingguo Tang | High school | Electrical engineer | After service | electrical engineer | 10 |

| Changqiang Li | High school | Maintain engineer | After service | machina maintain and install service | 10 |

| Haipin Li | University | Engineering director | Marketing and sales | project consulting | 8 |

| Sen Yang | University | Engineering translator | Marketing and sales | project consulting | 5 |

13.The Main Markets of HOOHA

14.FAQ of HOOHA

1.Who are we?

Hooha company Limited is based in Hongkong, china.Factory is located in dongguan,China.Established in 2003, with 19 years of experience in wire and cable field trade.It only takes 1 hour from our company to guangzhou/shenzhen airport.

|

|

15.Why chose HOOHA?

Before sales

1) 88 successful turnkey factory project .

2)Help over 28 clients from around the globe build their program from the ground.

3)Most humanized cable making solution provided by professional sales team with 10 years experience .

4)Complete access for all aspect of supply chain in professional cable industry with 18 years experience , including manufacturing material , technology , testing equipment , etc .

5)For 15 years , HOOHA stand alongside the client , considering and solving from the perspective of client’s marketing angle with all-around , precise and applicable solution .

6)HOOHA help saving the communication time cost for dealing with over dozens of supplier in the supply chain , mean while clients can generate much more value with same amount of time .

Middle sales

7)10 years experience engineer team for overseas cable and wire industry manufacturing and machinery installation and maintenance .

8)10 years experience engineer planing team for whole factory project including machinery , space layout , operational plan , water air electricity consume , raw material and such .

9)10 years experience professional team working on daily management and operation craft for cable and wire factory .

Vision

1)HOOHA is willing to grow with clients and achieve a mutual victory through business .

2)HOOHA spare no efforts to work for the future that all people is able to use clean electricity energy .