1.Description:

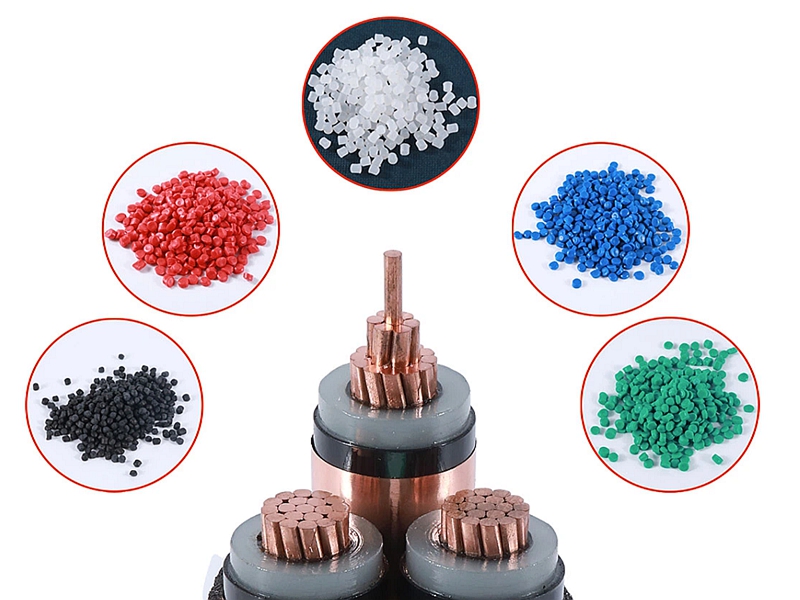

0535 cross-linkable semi-conductive shielding compound is used as conductor shield and bonded insulation shield for cross-linked polyethylene insulation power cable rated voltage up to 35KV. It's suitable for high temperature vulcanization processing method. 0535 provides fine surface smoothness, good extruding fluidity, low pre-cure or scorch characteristic, stable volume resistivity and compatibility with both copper and aluminum conductors, strong bonding with insulation layer.

0535 Cross-linkable Semi-conductive Inner Shielding Compound

1.Description:

0535 cross-linkable semi-conductive shielding compound is used as conductor shield and bonded insulation shield for cross-linked polyethylene insulation power cable rated voltage up to 35KV. It's suitable for high temperature vulcanization processing method. 0535 provides fine surface smoothness, good extruding fluidity, low pre-cure or scorch characteristic, stable volume resistivity and compatibility with both copper and aluminum conductors, strong bonding with insulation layer.

As 0535 bonded type was added in with special additive, it has excellence compatibility with copper conductor without formation of copper-oxidation.

2,Packing:In Cardboard Box with inner PE bag, 600kg/box.

3.Technical Parameter:

|

Property |

Test Method |

Unit |

Value |

|

Density at 23°C |

ASTM D 1505 |

g/ cm3 |

≤ 1.10 |

|

Tensile Strength (200 mm/min) |

ASTM D 638 |

MPA |

≥ 17 |

|

Elongation at Break before ageing |

ASTM D 638 |

% |

290 |

|

Volume Resistivity at 20°C |

ASTM-D991 |

W.cm |

20 |

|

Hot Set Test Conditions |

IEC 540-14 |

|

|

|

Elongation after loading |

|

% |

≤ 60 |

|

Moisture Content |

KARL FISCHER |

ppm |

≤ 500 |

|

Brittleness Temperature |

ASTM-D746 |

|

-40°C |

4,Processing Conditions:

The recommended standard extrusion temperature profiles are as followings: Unit: °C

|

Zone |

Zone 1 |

Zone 2 |

Zone 3 |

Zone 4 |

Flange |

Tube |

Screw |

|

Temperature Range°C |

85-90 |

95-100 |

105-110 |

110-115 |

110-112 |

110-115 |

65-70 |

We suggest using double layer filter mesh with size 40 mesh (350μm).

We recommend hopper drying at 40~60'C for 4 hours to remove moisture before extrusion.

5.Storage:

Should be stored at room temperatures between 10~30°C. Recommended maximum storage period in dry and clean are is 12 months unopened and in original packaging after the manufacture.