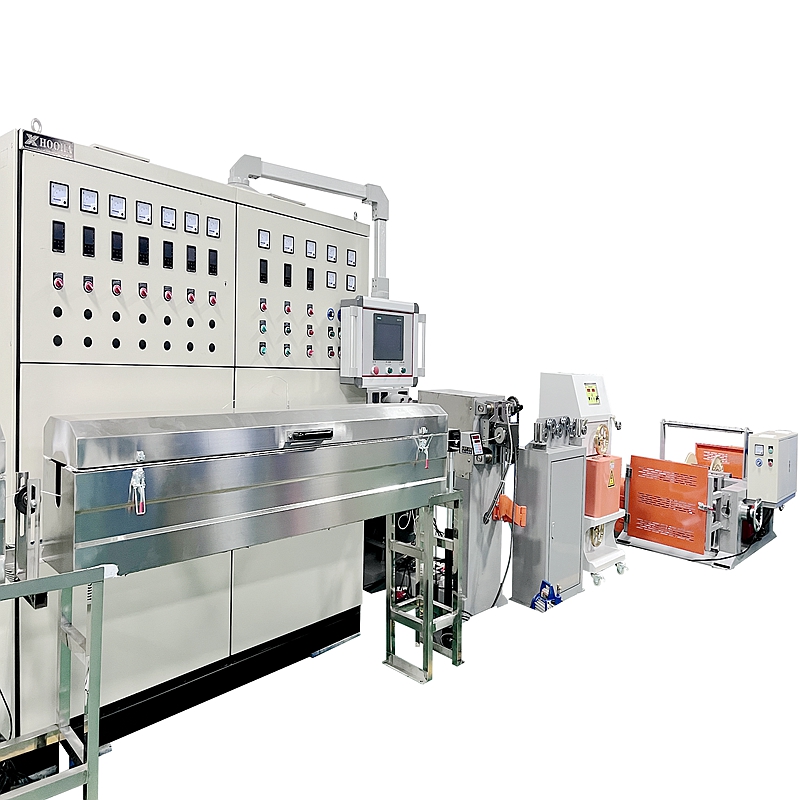

This silicone cable extrusion line is applicable for insulation and sheathing extruding for single, 2 cores, 3 cores silicone cables such as power cables, medical cables, control cables etc.

1. Using silicone rubber to avoid adjusting the die head, the water cooling system is automatically controlled or manually controlled.

2. It has a sophisticated test feedback system to ensure accurate wire diameter, thereby reducing costs.

3. PLC + touch screen control, parameter adjustment and monitoring of the entire production line.

4. Silicone rubber uses screw and barrel, crosshead and mold to prevent internal vulcanization.

|

No. |

Items |

Quantity |

Picture |

|

1 |

400-630 pay-off stand |

1 set |

|

|

2 |

5-wheel Straightening device |

1 set |

|

|

3 |

Copper wire preheating machine |

1 set |

|

|

4 |

65 Silicone extrusion machine with vacuum pump |

1 set |

|

|

5 |

PLC electric control box |

1 set |

|

|

6 |

Diameter tester |

1 set |

|

|

7 |

20m Electric heating curing chamber |

1 set |

|

|

8 |

High speed printing machine |

1 set |

|

|

9 |

9 meters accumulator stand |

1 set |

|

|

10 |

Dual wheels Capstan |

1 set |

|

|

11 |

Meter counter |

1 set |

|

|

12 |

High frequency spark tester |

1 set |

|

|

13 |

Powder machine |

1 set |

|

|

14 |

Double shaft take-up machine |

1 set |

|

|

15 |

Display board |

1 set |

|

|

16 |

Accessories |

|

|

|

No. |

Items |

Features |

|

1 |

Inlet Wire Diameter |

0.3-5.0mm |

|

2 |

Finished Wire Diameter |

1.8-8.0mm |

|

4 |

Extrusion Speed |

Max 80 m/min |

|

5 |

Extrusion Capacity |

60 kg/h |

|

6 |

Installed Capacity |

65 kva |

|

7 |

Voltage |

380V, can be customized |

|

8 |

Weight |

3500 kg |

|

9 |

Measurement (L*W*H) |

18*2*2 m |

|

10 |

Workers recommendation |

3 workers |

Our engineer team has more than 10-year experience working overseas for customer on-site service. which we can provide you widely range of support, such as overseas on-site installation, talent training, long-term technology updating services,etc.