Good news! The high-tech three layer chemical foaming extruder newly developed by the HOOHA technical department successfully passed testing and was delivered to our domestic customers, which is the top lan cable factory in China.

Here is a video of our machine running:

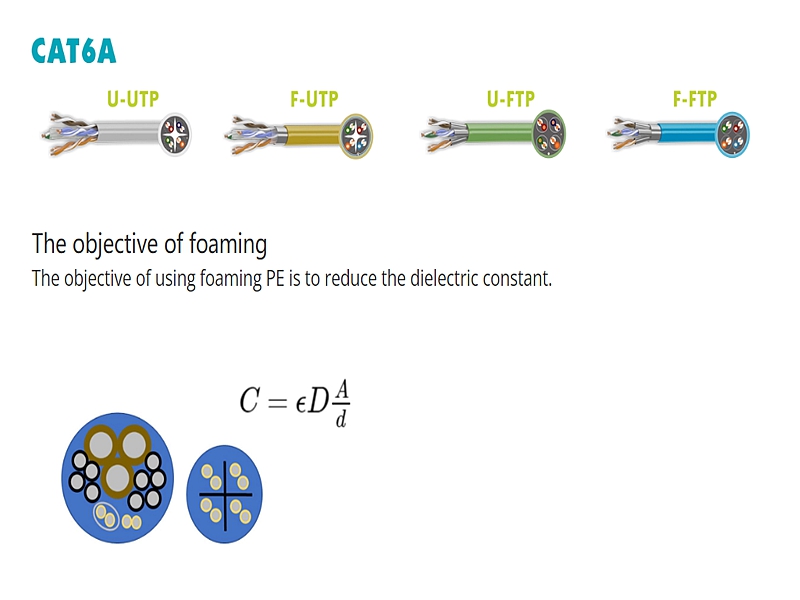

This machine is suitable for extrusion core wire of CAT.6A, CAT.7, high frequency cable and signal cable.

Product parameters:

1.Applicable material: Foam-PE

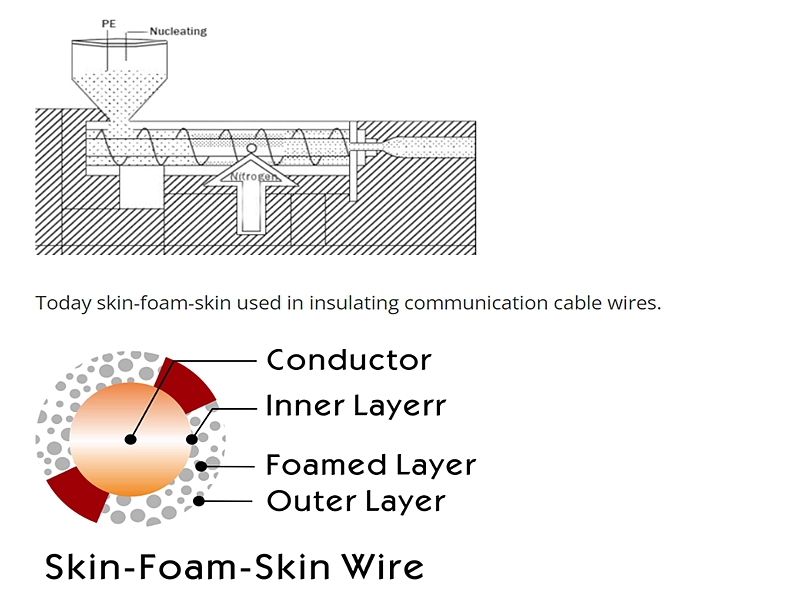

2.Insulation Way: Skin-Foam-Skin

3.Foaming degree:35%

4.Capacitance tolerance:±1PF

5.Diameter tolerance:±0.01

6.L/D of screw: 28:1

7.Compression ratio:3.0-3.2

8.Counductor O.D: 0.15-0.9mm

9.Insulation Diameter: 0.5-1.5mm

10.Max Line Speed: 500m/min

The inner layer is a low-density PE, the thickness is about 10μm closely adhered to the conductor

So that does not leave any gap between the two, and petroleum jelly prevent moisture penetration during the destruction of the longitudinal cable characteristics;

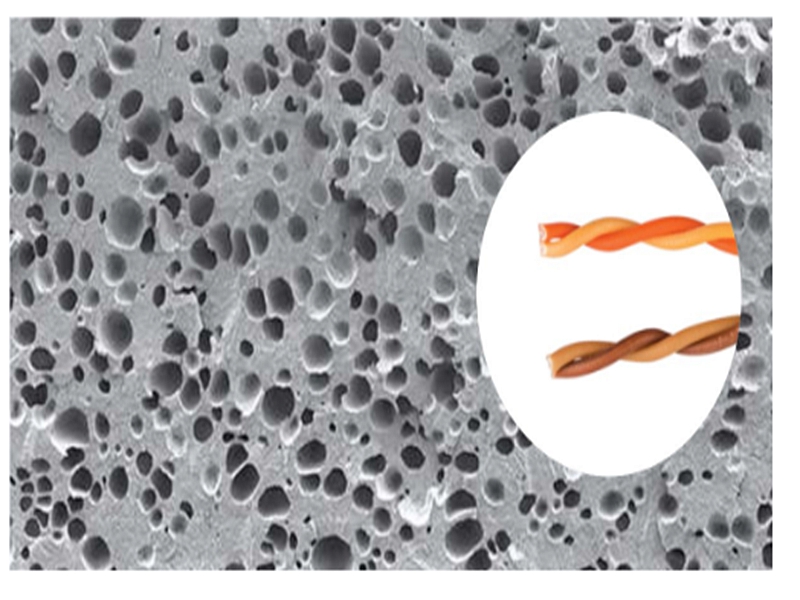

Foamed PE layer made substantial mixing from about 1% nucleating after extrusion machine injecting nitrogen form a uniform and closely integrated with the inner layer to avoid bubbles directly with non-continuous conductor adhesion and insulator loose.

Due to the absence of such concerns, the degree of foaming can be increased to 60%; the outer PE layer keeps a smooth appearance.